Le revêtement double nanocéramique résiste à 135 cycles thermiques sans décoloration et protège les ustensiles de cuisine pendant de longues périodes à 400-800°C..

L'acier inoxydable est très apprécié pour sa durabilité et son style distinctif. Cependant, même les produits en acier inoxydable de la plus haute qualité peuvent présenter un défaut majeur qui pourrait gâcher votre batterie de cuisine ou votre journée : la décoloration et la dégradation de la résistance aux rayures causées par une chaleur extrême. Les revêtements ordinaires se détériorent avec le temps sous l'effet de la chaleur, des produits de nettoyage et des chocs thermiques, ce qui entraîne la formation de taches, la décoloration des poêles et l'écaillage des revêtements.

Pourquoi les ustensiles de cuisine en acier inoxydable jaunissent-ils ? La science derrière la décoloration

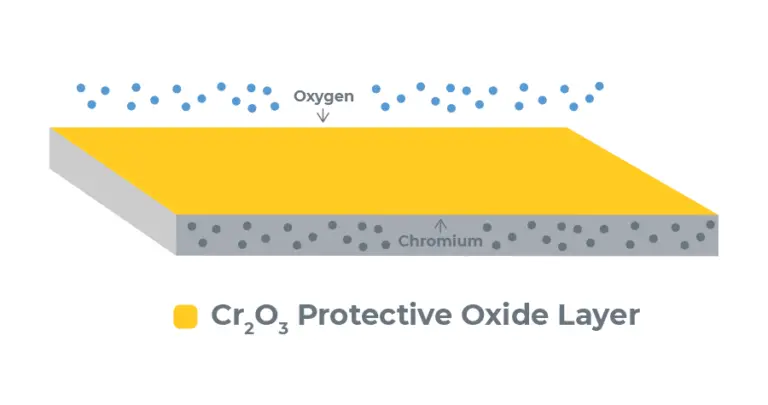

Oxydation à haute température

Lorsque la surface de l'acier inoxydable est exposée à des températures extrêmement élevées (plus de 400°C), elle réagit avec l'oxygène. Cela entraîne la formation de couches d'oxyde de chrome, qui apparaissent à la surface sous la forme d'une teinte jaunâtre ou brune. Avec le temps, ces oxydes s'épaississent, ce qui entraîne une coloration permanente.

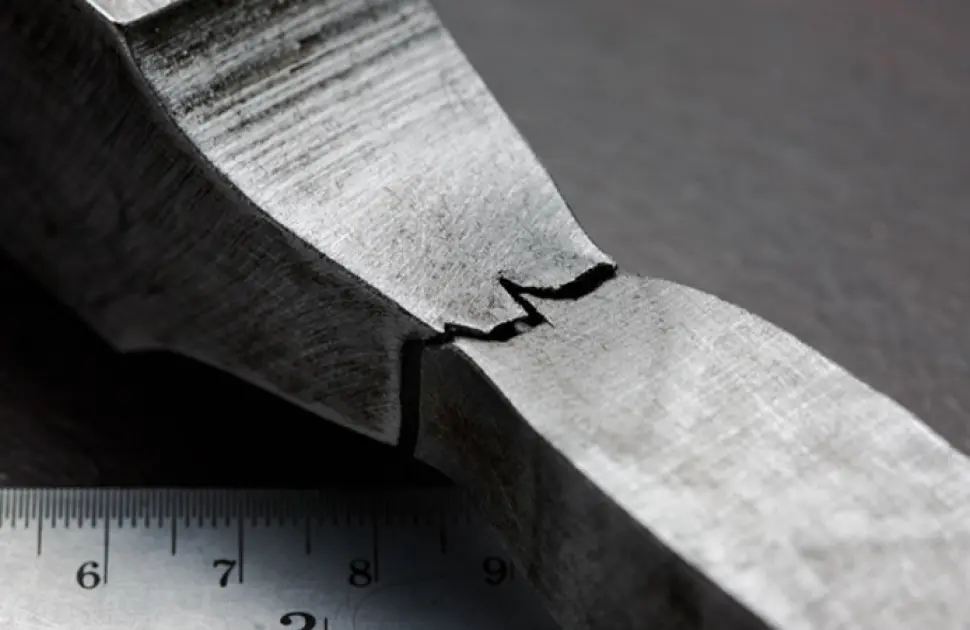

Modifications microstructurales

Le chauffage et le refroidissement répétés provoquent l'étirement et le rétrécissement de la structure en treillis du métal, un processus connu sous le nom de fatigue thermique. Ce processus affaiblit le matériau et accélère l'érosion de la surface.

Interactions chimiques

Les résidus de sel, les produits de nettoyage acides et les détergents s'infiltrent dans les pores fins ou les points faibles des revêtements, provoquant une corrosion électrochimique. Même l'acier inoxydable n'est pas à l'abri de ce processus.

Limites des revêtements conventionnels

De nombreux revêtements commerciaux sont basés sur des polymères organiques ou des silicones. Ces composés se décomposent rapidement sous l'effet de la chaleur, dégager des fumées toxiques à haute température. Les propriétés adhésives de ces revêtements se dégradent au fil du temps, ce qui entraîne des recouvrements fréquents et l'insatisfaction des clients.

Protection double nanocéramique : Comment ça marche

Le système de revêtement à double nanocéramique comporte deux couches puissantes qui constituent une barrière impénétrable contre la chaleur, les produits chimiques, les rayures et l'abrasion :

Couche 1 : Primaire anti-oxydation haute température

Ce primaire inorganique à base d'eau sert de couche de base pour les revêtements de barrière thermique.

Caractéristiques principales:

- Stabilité à la chaleur: Résiste à des températures de 400-800°C sans se déformer.

- DuretéDureté du crayon : ≥5H pour la résistance aux rayures.

- Couverture ultra-mince: Environ 1μm d'épaisseur, ce qui n'affecte pas les performances.

- Séchage rapide: Sèche au toucher en 1-3 minutes à température ambiante ou à 60-80°C pendant 1 minute.

La matrice de silice nanostructurée de l'apprêt réagit chimiquement avec la surface du métal, créant une barrière qui limite l'oxydation au niveau atomique.

Couche 2 : couche de finition nanocéramique anti-jaunissement à haute température

La deuxième couche protège la surface contre l'exposition aux UV, l'abrasion et les attaques chimiques.

Caractéristiques principales:

- Formule nanocéramique: Crée une barrière hydrophobe ultra-dense grâce à des nanoparticules de céramique solubles dans l'eau.

- 9H Dureté du crayon: Offre une protection extrême contre les rayures, supérieure à celle de l'acier et d'autres matériaux résistants.

- Résistance aux chocs thermiques: Peut résister à de brusques changements de température, de la combustion sèche à 400°C à la trempe dans l'eau glacée.

- Caractéristiques antiadhésives: Facilite le nettoyage en réduisant l'adhérence des aliments.

Synergie des deux couches: La combinaison des deux couches forme un bouclier ultra-mince (moins de 11 μm) qui offre une résistance à l'oxydation et une durabilité mécanique. Le primaire empêche la détérioration de la sous-surface, tandis que la couche de finition résiste à la chaleur et à l'usure, conservant à l'acier inoxydable son aspect brillant et comme neuf.

Validation des performances : Tests en laboratoire et en conditions réelles

Résistance aux chocs thermiques

- Test: 135 cycles de brûlage à sec à 400°C suivis d'une trempe à l'eau froide.

- Résultats: Aucune modification visible de la couleur, et la finition brillante reste intacte.

- Importance: Elle indique la résistance aux changements brusques de température pendant la cuisson ou le nettoyage.

Résistance aux hautes températures

- Test : Exposition pendant 30 minutes à 1100°C (bien au-dessus des températures de cuisson normales).

- Résultats : Pas de farinage, de décollement ou de défaillance structurelle. Un léger grisonnement a été observé, mais l'adhérence est restée forte.

- Application Insight : Il est donc parfait pour les cuisinières à induction et pour saisir les aliments à très haute température.

Mesure de la durabilité d'un revêtement nanocéramique double

- Essai au brouillard salin: Testé pendant 500 heures, aucune corrosion n'a été observée, dépassant les normes industrielles.

- Résistance à l'abrasionLa perte de poids n'est que de 10 mg : 2 134 cycles sur le tampon de dépoussiérage 3M 7447.

- Résistance chimique: A résisté à 12 heures de séchage en profondeur dans de l'eau salée 5% et à 8 heures de test au détergent.

- Durabilité de l'anti-adhérence: Réussir cinq cycles de cuisson d'œufs à des températures comprises entre 170 et 190°C.

- Certification FDA: Selon les tests de l'entreprise, les extractibles sont ≤18 mg/in², soit plus de 100 fois inférieurs à la limite réglementaire.

Spécifications techniques et guide d'application

Compatibilité des matériaux

- Métaux: Acier inoxydable, acier au carbone, aluminium, alliage de titane.

- Substrats: Corps, couvercles, poignées et pièces affectées par la chaleur des ustensiles de cuisine.

Processus de candidature

- Préparation de la surface: Nettoyer et dégraisser complètement les substrats. Porter des gants pour éviter toute contamination.

- Application de l'apprêt: Dispersion à travers une buse de 0,35 mm à une pression de 2 à 4 bars, assurant une épaisseur régulière de 1 μm.

- Application de la couche de finition: Mélanger les composants A et B (tamisés à travers 400+ mesh), pulvériser avec une buse de 0,8-1,0 mm pour une couverture de ≤10 microns.

- Durcissement: Cuire au four à 230-250°C pendant 20-30 minutes. Laisser refroidir à température ambiante avant utilisation.

Stockage et manutention

- Durée de conservation: 3 mois à une température de stockage de 5-25°C.

- Conseil d'application: Utiliser des outils distincts pour chaque couche afin d'éviter toute contamination croisée.

Pourquoi la protection par double revêtement nanocéramique est-elle meilleure que celle des concurrents ?

| Fonctionnalité | Double nanocéramique | Revêtement conventionnel |

| Stabilité thermique | 400-800°C | Max 300°C |

| Respect de l'environnement | Sans COV, à base d'eau | A base de solvants (fumées toxiques) |

| Conformité à la FDA | Oui (21 CFR 175.300) | Souvent non conformes |

| Résistance à l'abrasion | 2 134+ cycles | <500 cycles |

| Test de choc thermique | 135 cycles, aucun échec | 10 à 20 cycles, jusqu'à l'échec |

Résultats

Le revêtement double nanocéramique est la dernière innovation en matière de technologie antiadhésive métallique. Des essais et un développement approfondis du produit ont montré qu'il résout complètement les problèmes de jaunissement, d'écaillage et d'émissions de vapeurs toxiques qui existent depuis longtemps. Il intègre la prévention de l'oxydation au niveau moléculaire et la résistance thermique et chimique au niveau de la surface.

Avantages pour les producteurs et les vendeurs

- Durabilité et longévité: Les marmites peuvent durer des dizaines d'années, même en cas d'utilisation intensive dans les cuisines professionnelles et domestiques.

- Conformité: Conforme aux réglementations de la FDA en matière de contact alimentaire.

- Satisfaction des clients: Conserve son aspect parfait plus longtemps, même lorsqu'il est exposé à des éléments extérieurs tels que le soleil, sans se fissurer ni se décolorer.

Prêt à être la prochaine vague de votre gamme de produits ? Faites équipe avec nous pour apporter des revêtements en double nanocéramique à votre gamme de produits. Contactez-nous pour savoir comment votre marque peut devenir un leader dans le domaine des ustensiles de cuisine de haute qualité et de longue durée.

A propos de nous

Purecook est un fabricant professionnel d'ustensiles de cuisineNous fournissons ustensiles de cuisine en gros services et solutions d'ustensiles de cuisine sur mesure à des marques et des détaillants internationaux. Chaque ustensile de cuisine Purecook est le fruit d'un savoir-faire exquis et de 30 ans d'innovation silencieuse.

Des solutions OEM et ODM personnalisées aux services de vente directe à l'usine, Purecook est le premier choix des grossistes, des détaillants et des marques de cuisine du monde entier.

Nous ne sommes pas seulement un fabricant d'ustensiles de cuisine, mais aussi un partenaire solide de la cuisine mondiale. Nos ustensiles de cuisine sont vendus dans le monde entier, ce qui permet de relier les délices et les températures du monde entier.