Surface finishing is often mischaracterized as a cosmetic step. For stainless steel cookware, it is a functional, regulatory, and commercial decision. Correct cookware surface treatment directly affects food safety, corrosion resistance, cleaning performance, thermal behavior, and the long-term cost of warranty and returns.

As a professional stainless steel cookware manufacturer, we deeply understand the importance of cookware surface treatment in product performance and safety. In this blog post, we will systematically explain why manufacturers and purchasing teams must treat cookware surface treatment as an engineering decision, not just a choice based on aesthetics.

Surface Treatment: A Functional Definition

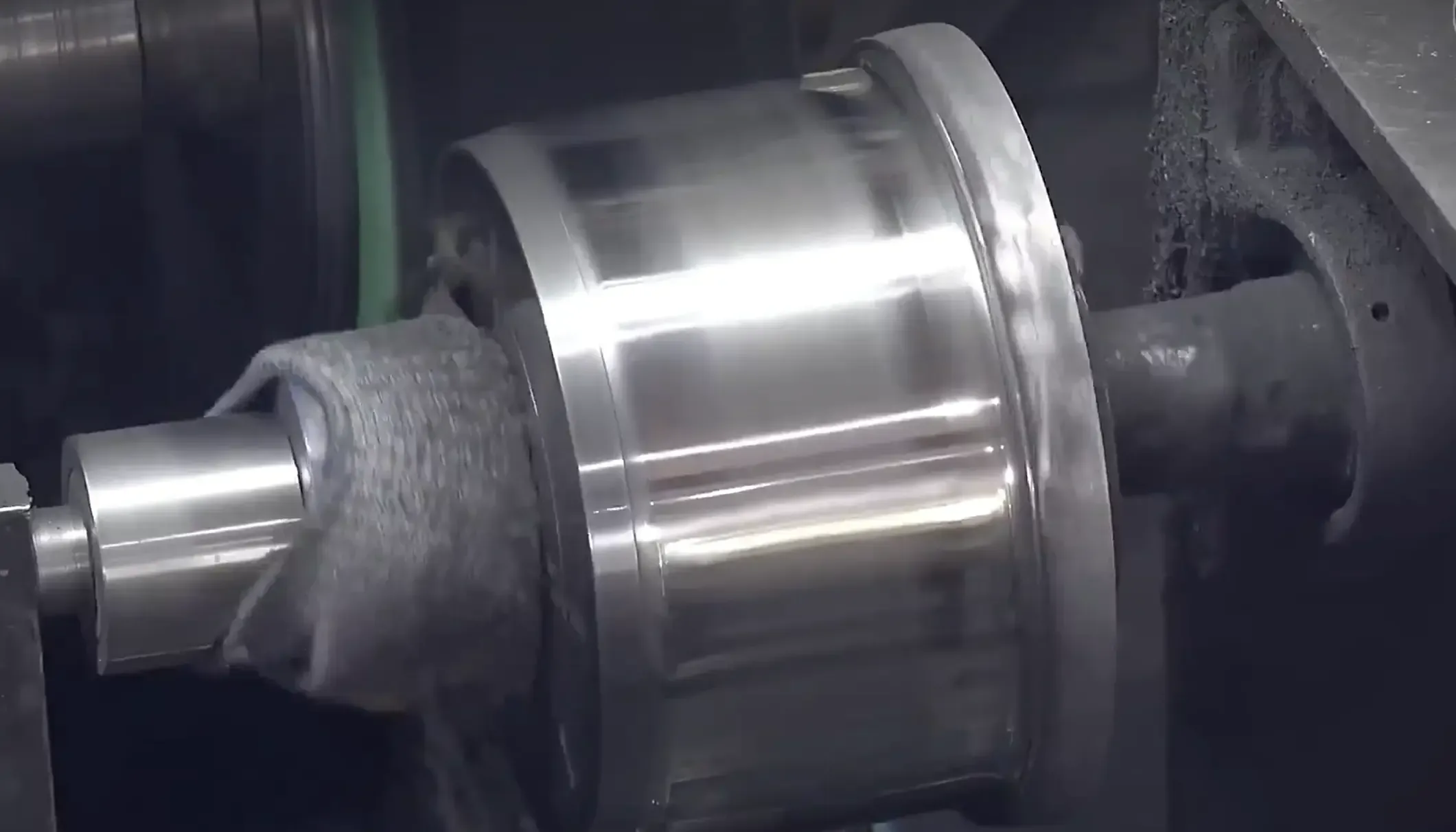

Cookware surface treatment refers to mechanical, chemical, or electrochemical processes that change the topography, chemistry, or coating of stainless steel surfaces, which is rather significant in high-end wholesale cookware markets.

Common methods used in cookware production include mechanical polishing (mirror and satin), electropolishing, passivation, targeted surface texturing, laser marking, and exterior coatings (PVD, paint) when required.

Crucially, interior (food-contact) and exterior (non-food-contact) surfaces have different performance goals and therefore different acceptable treatments.

Why It Matters — Five Operational Impacts

Food safety and regulatory compliance

Cookware surface treatment of interior finishes influence migration and contamination risk. A poorly prepared surface traps iron particles and residues that accelerate corrosion and can fail food-contact migration tests. Specifying proper electropolishing or controlled Ra values helps ensure compliance with food-contact standards and reduces regulatory risk.

Corrosion resistance and discoloration control

Surface chemistry and roughness determine how well the stainless steel passive layer performs. Passivation and electropolishing remove embedded iron and promote a stable chromium oxide film—key to resisting pitting and stains from acidic or salty foods, and from dishwasher cycles.

Cleaning performance and consumer experience

Low roughness (measured as Ra) reduces soil retention, shortens cleaning time, and improves perceived hygiene. Interior finishes that meet cleanability targets reduce consumer complaints and lower AUR (after-use returns). In premiums, the Ra value is usually required to be between 0.2-0.4 µm. 0.8 µm may only be considered as an “industrial grade” or “entry-level” standard for B-end customers.

Thermal behavior and mechanical durability

Cookware surface treatment affects heat transfer and thermal stress behavior—particularly when coatings are applied. Rough substrates can cause premature coating failure; inconsistent finishing can produce hotspots and accelerate warping. For tri-ply or clad cookware, correct finishing prior to bonding preserves flatness and long-term stability.

Brand perception and resale value

When wholesale cookware, exterior finishes (brushed vs mirror vs PVD) are often the first quality signal to buyers. Inconsistent finishes or visible defects reduce perceived quality and damage retail performance even if the metallurgy is sound.

Interior Vs. Exterior: Separate Specifications

Treat interior and exterior surfaces as separate engineering deliverables.

Interior (food-contact) requirements

- Primary goals: inertness, low Ra, hygienic cleanability, and migration compliance.

- Typical treatments: fine mechanical polish (specified Ra), electropolishing, and passivation after welding or machining.

- Metrics to require: Ra value (e.g., ≤0.8 µm), passivation certificate, and third-party migration or CoA for coatings.

Exterior (non-food contact) requirements

- Primary goals: durability, scratch resistance, brand finish, and thermal stability.

- Typical treatments: brushed/satin or mirror polishing, PVD decorative coatings, and laser marking.

- Metrics to require: adhesion and abrasion test results for coatings, visual tolerance, and color fastness under heat.

Common Production Problems (and How Cookware Surface Treatment Prevents Them)

- Embedded iron after forming: causes early rusting—prevent with passivation and controlled cleaning.

- Inconsistent Ra across batches: causes uneven coating adhesion—control with process SOPs and Ra measurements.

- Poor weld-area treatment: weld heat-affected zones without passivation lead to corrosion—include post-weld passivation in SOPs.

- Improper coating on unprepared surfaces: leads to delamination—requires pre-treatment and adhesion test results.

Quality Control: What to Require from Suppliers

Specify objective, testable acceptance criteria in RFQs and contracts are instrumental when buying wholesale cookware. Essential QC items:

- Surface roughness (Ra): specify values for interior/exterior. Provide measurement methods and specific parts.

- Passivation certificate: include method and reagent (e.g., citric or nitric), and CoA.

- Electropolish report: current density, material removal, and Ra before/after.

- Adhesion and abrasion tests: for PVD and painted exteriors (cross-cut, Taber).

- Peel/adhesion tests: if bonding multilayer components.

- Thermal cycling: simulate real-life dishwasher/oven cycles to show no delamination or discoloration.

- Third-party verification: recommend periodic lab testing and factory acceptance tests (FAT).

How Buyers Should Write RFQs for Cookware Surface Treatment

An RFQ should separate structural metallurgy from cookware surface treatment specification. Include:

- Material composition and grade for each layer (e.g., 304/Al/304 or 430/Al/430 for induction compatibility).

- Interior finish: target Ra, electropolish/passivation requirement, and post-weld treatment.

- Exterior finish: finish type, gloss or satin level, coating spec (if any), and adhesion thresholds.

- Test protocol: list required lab tests (Ra measurement, peel test, salt spray, thermal cycles).

- Batch traceability and CoAs: require batch IDs and material certificates(FDA, etc.) with each shipment.

- Sample approval: define first article inspection (FAI) acceptance criteria and allowable variance.

Providing clear, measurable targets prevents ambiguity and protects both buyer and supplier.

Commercial Impacts and ROI

Investing in correct cookware surface treatment reduces warranty returns, lowers customer complaints, and shortens time-to-shelf by avoiding rework. Poor finishing increases after-sale service costs and brand dilution. Quantify ROI for procurement by modelling reduced return rates and longer product lifetimes against incremental finishing cost—often a straightforward justification for premium lines.

Conclusion

In stainless steel cookware production, cookware surface treatment is a cross-functional lever: it touches compliance, manufacturability, consumer satisfaction, and brand value. Treat surface specification as an engineering requirement—define measurable criteria, require documentation, and include test protocols in procurement contracts. Doing so converts a historically subjective process into a predictable, auditable production outcome that protects margins and strengthens market position.

About Purecook

I am quite glad to share as much as I know in the field we are devoted to. As one of the leading stainless steel kitchenware manufacturers, Purecook is in pursuit of benefiting our clients with our expertise in wholesale cookware procurements. If you have some fancy ideas about cookware, our high-production factory and professional teams are capable of offering custom cookware solutions for you.

Working together with Purecook to get:

✅Well-quality-controlled cookware supply

🌟Unique custom cookware solutions

⚙️Stable and high-speed production

📦Bulk inventory supply